Caster Terminology

In order to correctly select a caster, one must first become acquainted with the terminology used when referring to casters. Below is a table defining various caster terms that may assist you when choosing the correct caster for your needs.

In order to correctly select a caster, one must first become acquainted with the terminology used when referring to casters. Below is a table defining various caster terms that may assist you when choosing the correct caster for your needs.

It may also be helpful to consult the other reference materials OneMonroe has provided in the casters section of our site. If there are any further questions or concerns, feel free to direct them towards one of OneMonroe's helpful sales representatives.

Bolt Hole Spacing: The distance between top plate bolt holes.

Capacity – The maximum load per caster or wheel recommended for intermittent operation over smooth floors at speeds of 3 m.p.h. or less. (Gross weight should be divided by the number of casters or wheels on which it is distributed.)

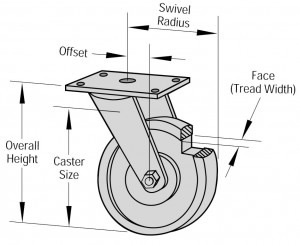

Caster Size – A loose term for classifying casters, based on the nominal diameter of the wheel. For example: a “6 inch caster“ is any caster having a 6 inch diameter wheel.

Component Thrust – Designates side forces exerted on a swivel caster and properly counteracted by the secondary load bearing.

Direct Thrust – Designates those downward forces exerted on a caster by the load, and counteracted by the main load bearing.

Durometer – A measure of the hardness of resilient tread wheels. Face – The width of the wheel tread cross-section, measured at the base of the tread rather than at the point of floor contact.

Dynamic or Rolling Load: Load on a caster or wheel while in motion.

Fork Assembly (Rig or Yoke): The casterassembly without wheel and axle.

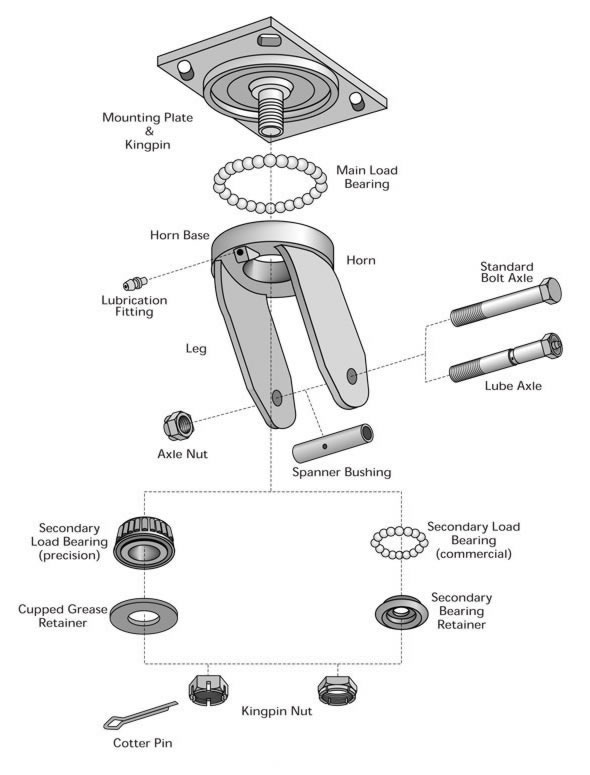

Horn – The caster part which comprises legs, plus a base (horn base of swivel caster or mounting plate of rigid).

Horn Base – The flat part at the top of the horn from which the legs extend. Serves as lower raceway for main load bearing, and may provide a seat or upper raceway for secondary load bearing.

King Pin – A rivet, or threaded stud or bolt with nut, that holds the mounting plate and horn assembly of a swivel caster together. Forged as an integral part of mounting plate on higher quality casters for maximum rigidity and strength.

King Pin Nut – The nut on the bottom of a threaded king pin or bolt that permits the disassembly or adjustment of swiveling components; a maintenance feature of better casters not found with rivet type king pins.

Legs – The axle support brackets extending down from the horn base of a swivel caster, or from the mounting plate of a rigid caster.

Load Height: Vertical distance from top surfaceof top plate to the bottom of the wheel.

Main Load Bearing – The row of steel balls or rollers that swivels the horn base in relation to the mounting plate of a swivel caster, and counteracts direct thrust.

Mounting Plate – The flat base, usually with four bolt holes, that forms the top of a caster and permits attachment by bolting or welding to a flat surface.

Offset – (swivel lead) The perpendicular distance between the vertical centerlines of the king pin and the axle of a swivel caster. Larger offsets afford easier swiveling, shorter offsets greater strength.

Overall Height – The vertical distances from the top of the caster mounting plate to the bottom of the wheel.

Raceway – A surface in which bearing balls or rollers rotate.

Retaining Washer – A steel washer pressed into the hub ends of some roller bearing wheels to hold the bearing in place.

Rig – A swivel or rigid caster assembly less wheel, that may or may not include axle, nut or spanner bushing.

Rockwell C – System for measuring hardness of metals.

Rollability – Ease of starting and rolling, measured by drawbar pull. This is determined by load, floor conditions, and type and size of wheels and bearings.

Secondary Load Bearing (Commercial) – The row of steel balls that rides in the raceway between the horn base and secondary bearing retainer of a swivel caster to counteract component thrust. It is this bearing that characterizes the popular “double ball race” caster.

Secondary Load Bearing (Precision) – A precision self contained bearing, usually a tapered roller bearing, operating between the horn base and the king pin of a swivel caster. Constitutes the most efficient means of assisting swivel action by counteracting component thrust.

Spanner Bushing – A non-rotating sleeve of seamless steel tubing that fits over the axle in many casters. Serves the dual purpose of providing a smooth inner raceway for the wheel bearings, and strengthening the caster by permitting the legs to be tightened against it.

Static Load: Load on a caster or wheel while at rest.

Swivel Radius – The horizontal distance from the centerline of the caster king pin to the outer edge of the wheel (a measure of clearance required to swivel a caster 360°).

Thrust Washer – A steel washer between the hub ends of the wheel and the inside of the caster legs.

Tread Width (Face): Width of the wheel tread.

Yoke – Alternate term for horn.

Are you looking for casters?

Submit an RFQ now!